I was getting as much as a hundred feet per second spread in my velocities so I checked with Steve. He asked about the brass. I told him, "man I have no idea how many times I fired that brass," so he suggested I try some new brass. I did. While I was at it I decided to do a crimp test also since, well since that's what I do. Steve was right.

I used the same six pieces of brass throughout. Maybe you notice the velocities are way more consistent compared to the worn out brass.

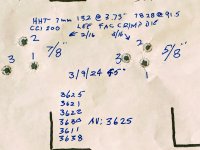

Here are the results:

I used the same six pieces of brass throughout. Maybe you notice the velocities are way more consistent compared to the worn out brass.

Here are the results: