(Originally posted 4/24/2020)

ButterBean

Platinum Member

Before I open up the age old argument of to Crimp or not to Crimp I just want to say this is my process and it works for me ,I'm not trying to push it on anybody or saying that what anyone is doing is wrong, I love reloading and I have spent a small fortune on the latest and greatest and 30 years later I have come full circle and am almost where I started finding I can do a lot with a little. Anyway The Lee FCD, It comes with instructions and they work fine set to those specs but here is how I use it to "Fine Tune", Back the die way off and raise a round, screw the die in until it tightens up against the round, (Hand tighten really snug and I take a fine line sharpie and mark the die, lock nut and press at this point for reference), lower the round and give it a 16th to 1/8th or so of a turn, ( I prefer to cam over doing this with the Rock Chucker press so I know I'm consistent ) it may not look like it did anything but I assure you it did, crimp a string of however many you want and see if it helps, if it didn't give it another 16th to an 1/8th of a turn in and repeat. You can take bigger swings if you like but I don't .The way I use the Lee FCD its the same as finding a powder charge or seating depth. Once again I'm no professional and I'm not a competition shooter I'm a hunter who loves fast accurate rifles and this works for me and i use it on everything I load for, I have seen it help various calibers and I will say that I personally have never seen it hurt one in any way, The problem I was having with the 30 Cal 124 was lack of baring surface in the case neck, The FCD equalized things providing a more consistent initial burn and bullet release time, and I made a big gain in everything and I mean big, I will say that in my load development with conventional bullets this was the last thing I did after establishing a load but in my short time of working with Hammer Bullets I would suggest to start with a light crimp from the start of initial load development for a known constant bullet release , The reason I started crimping in the first place is another story that I revisited last week because i was in a hurry and it came back to bite me ...... again but that's another story, I do a lot of unconventional things from the Case Lube or the Dies I like to use some folks think I'm crazy I reckon, Once again this is just how I do things, I just want to say this again so it doesn't get all twisted,

ButterBean

bc sportsman

Full Member

Thanks for this BB!

So do you suggest a light crimp when working up a first time load for Hammer bullets, then when you get good results, change seating depth to optimize, the play a bit by increasing crimp?

Or, increase crimp first to find a good place, then change bullet seating depth?

mcd

Senior Member

Butterbean,

Do you recommend disassembling the die and greasing it prior to use? Maybe even lightly debur the collet edges? I really wish Lee’s quality at the source was a lot better. I’ve heard a lot of folks just leave the burrs, and they don’t seem to hurt much other than scoring the case potentially, or maybe not, just depending on where they are.

I've not had any neck scoring with my Lee FCD loading for my 375 H&H mag. I use several compressed loads and this keeps the bullet from extruding (realistically that didn't happen before I crimped). My OCD side just wants to be sure! GJ

mcd

Senior Member

Just rechecked my FCD, and mine actually looks pretty good as far as finishing of the collets. It's my Lee neck sizing collet die that is heavily burred, also never used. For those that use the crimp die, based on the type of bullet and seating depth, I could see quite a bit of variation in the crimper's position, correct. This is not a one and done, but rather a specific setting per bullet selected, and in the case of the Hammers, seating depth too. Is that correct?

bc sportsman

Full Member

I have developed close to max loads in my two rifles.

Fierce 300WM,166HH,F215M,new GW brass, 79.0 gr R23,3358 fps

Sako Finnlight 20" barrel,308Win,152HH,F215M,new Lapua brass, 45.0 gr ARComp, 2918 fps

Im going to be shooting for groups by fine tuning using incremental increases in crimp pressure, based on Butterbeans good advice to me.

Will probably shoot later this coming week and will post results (change in velocity, grouping, bolt extraction, case dimensions).

ButterBean

Platinum Member

Bud I apologize as I just saw this and yes i disassemble and grease but I have never had any quality issues wit Lee Products

mcd

Senior Member

No problem. I had confused my Lee neck sizer (unused) with my crimp die. I’ve been crimping for a while now.

farleg

Platinum Member

All I can say is the biggest thing I like is how this fits perfectly in with the kiss system & that’s me through & through

Thanks & Cheers

mbruce

Platinum Member

mcd will like this...

Crimping is an alternative to bushings -- more or less.

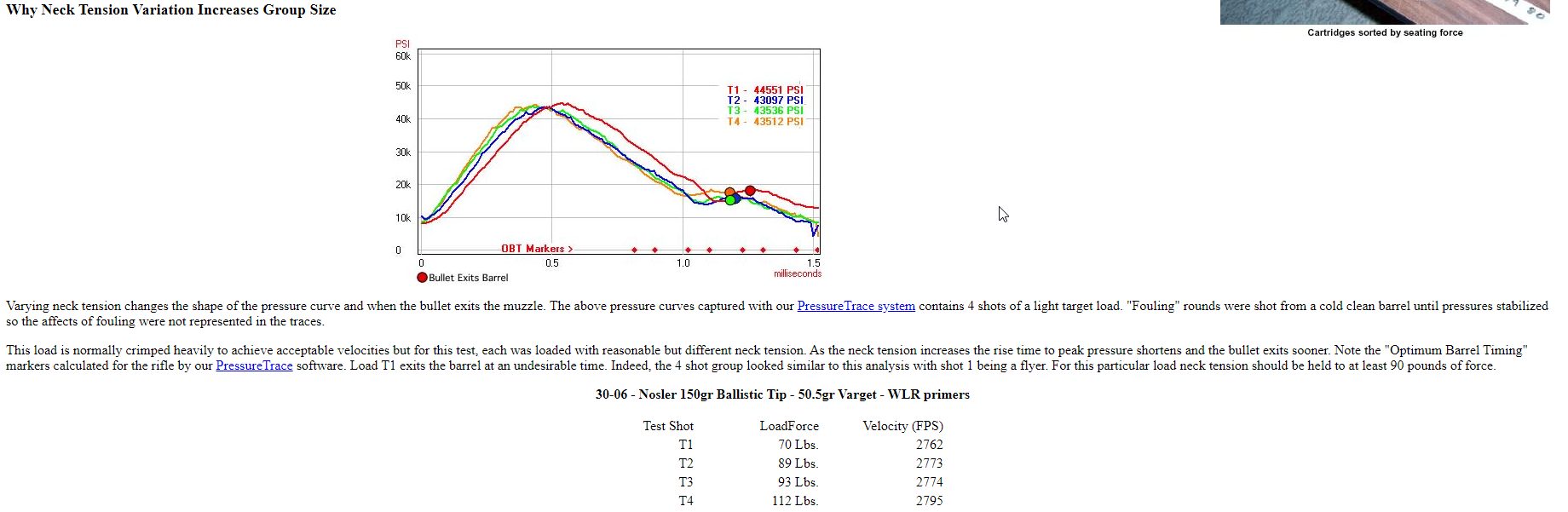

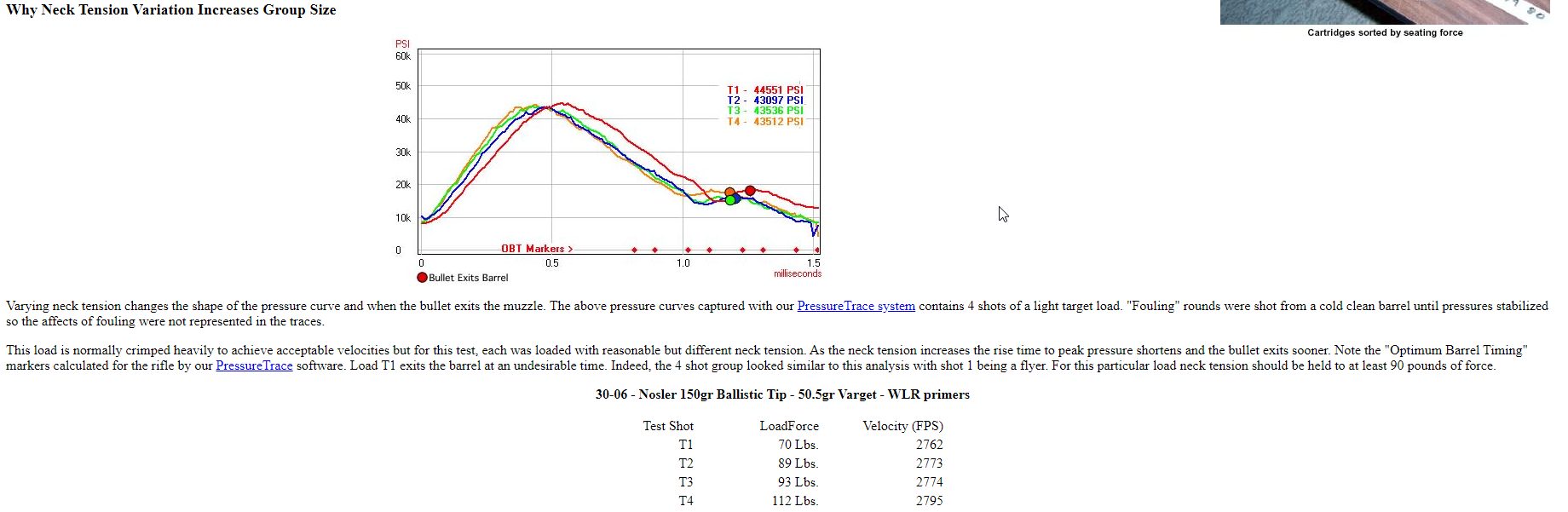

The reason why neck tension influences precision is it impacts the pressure curve, ultimately impacting optimal bullet time. Your internal ballistics and barrel will heavily prefer a specific curve.

Here's Pressure Trace demonstrating variable neck tension effects: (Found here: www.shootingsoftware.com/recoil.htm)

mcd

Senior Member

Very cool! I think the two most significant pieces of equipment I’ve procured over the last couple years are the LabRadar and the Pressure Trace II. Between the two, so much useful information is available.

ButterBean

Platinum Member

Thank you so much, I have been trying to tell folks this for decades, I'm really excited over the graph

joliver

Full Member

Thanks guys! I just ordered dies for all my calibers it makes sense to me especially with hammers. My load development is on hold until my crimp dies come in

joliver

Full Member

I grew impatient waiting for crimp dies. Beautiful day and all. I had some .270 win’s loaded with 85gr shock hammers. I do believe I just saw on the chrono exactly what everyone who crimps is talking about!!!

joliver

Full Member

All varying charge weights looking for pressure. From 55-58 the last one was 58.5.

as you can see velocity hits it’s high at 57gr. Then proceeds to drop off at 58 and 58.5. I feel like I’m loosing velocity due to improper powder burn because of no crimp. Grouping was all touching each other. Thoughts!?

ButterBean

Platinum Member

It'll help it

cbjr

Senior Member

Ok, Question. Where, on the hammers, do you crimp? After the pdr section, on the high spots of the pdr, or in the valleys between? Could it be I'm just reading this wrong and there are multiple places to do this?

Thanks

Edit: How much neck tension do you use vs. no crimp?

joliver

Full Member

Just saw this sorry for the delayed response. I'm new to this as too. but i plan on just running it through the crimp die as Bean described. I did this over the weekend. I honestly can't tell a difference by looking at the neck. I haven't measured but i could hear an audible squeak as i ran the loads through the die. I didn't pay much attention to where i crimped it was just where ever they were seated but my loads do appear to be right on one of the valleys. Just coincidence thought.

ButterBean

Platinum Member

.003-.004 on the neck tension and crimp in the valley is what I have been doing

cbjr

Senior Member

Thanks for the clarification, BB!

mbruce

Platinum Member

Would die shims be useful for the FCD....I'm thinking about absolute repeatability when toying with adjustments. May be overkill for its application...but so is 90% of reloading. ha

benchrite.com/skips-7-8-14-sizing-die-shims/

ButterBean

Platinum Member

It would just be another way to fine tune it, It probably is overkill but who knows, I'm always willing to learn something new

shinbone

Junior Member

bcsportsman - maybe I missed it, but have you posted any results from your testing, yet?

bc sportsman

Full Member

Here is my data on both my 300WM and 308 Win using two different powders for each. I used Redding Dry Lube when seating bullets and neck tension was 4 thou for both cartridges using K&M expander mandrell.

My best group for 300WM turned out to be 79.0 gr of R23 at 10lb crimp pressure using the Consistent Crimp tool from Titan reloading. I did test loads with 5 and 10 lbs just to see what effect they had on velocity. I haven't had the time to play with different crimp pressures to fine tune my 300WM best accuracy load which was 10 lb crimp of 79.0 gr R23. Hope to do so later this month.

I also saw no signs of excessive pressure on brass and couldn't tell if the bolt extraction changed. Bolt extraction never seemed "hard" with any loads but may have progressively increased without me noticing. I measured the length of the GW 300WM fired brass. Brass was 2.610 - 2.612" before firing.

I tested various crimp pressure for my 308Win. 35 inch/lbs gave good group, about half the size of the rest which were from 1" to 2". Amazing how they settled down at 35 lbs, then opened up again.

Fierce 300 WM (MAX COAL 3.58": COAL 3.49": CBTO 2.797": Case Length ~2.611")

166 HH, Fed 215M Primers, New Gunwerks Brass

Crimp = 5 lb Crimp = 10 lb Case Length After Firing

R23 75.0 gr 3215 3208 2.6175

R23 76.0 gr 3246 3278 2.6150

R23 77.0 gr 3263 3295 2.6175

R23 77.5 gr 3303 2.6175

R23 78.0 gr 3326 2.6140 Online Data Max

R23 78.5 gr 3352 2.6145

R23 79.0 gr 3364 2.6150

1st Shot 2nd Shot 3rd Shot 4th Shot

R23 10 lb Crimp 77.0 gr 3304 3288

R23 10 lb Crimp 78.0 gr 3333 3333 3325 3340

R23 10 lb Crimp 78.5 gr 3372 3344 3348 3359

R23 10 lb Crimp 79.0 gr 3362 3370 3365 3360 Most Accurate 0.6"

Crimp = 5 lb

R16 68.0 gr

R16 69.0 gr 3054

R16 69.5 gr 3122

R16 70.0 gr 3126

R16 71.0 gr 3170

R16 71.5 gr 3179

R16 72.0 gr 3218

R16 72.5 gr 3271 Online Manual Data Max

R16 73.0 gr 3266

R16 73.5 gr 3286

Sako Finnlight 308W (MAX COAL 2.828": COAL 2.7673": CBTO 2.1685": Case Length ~2.010")

152HH, Fed 215M Primers, New Lapua Brass

Crimp = 5 lb

XBR8208 40.0 gr 2571

XBR8208 41.0 gr 2649

XBR8208 41.5 gr 2670

XBR8208 42.0 gr 2695

XBR8208 42.5 gr 2717

XBR8208 43.0 gr 2748

XBR8208 43.5 gr 2789

XBR8208 44.0 gr 2825

XBR8208 44.5 gr Shot not recorded Online Data Max

XBR8208 45.0 gr 2855

XBR8208 45.5 gr 2891

5 lb crimp No crimp

ARComp 41.0 gr 2728

ARComp 41.5 gr 2745

ARComp 42.0 gr 2757

ARComp 42.5 gr 2768 2796

ARComp 43.0 gr 2817 2805

ARComp 43.5 gr 2839

ARComp 44.0 gr 2873 Online Data Max

ARComp 44.5 gr 2895

ARComp 45.0 gr 2919

AR Comp 45.0 gr

0 lb crimp 2918 2914 2915

5 lb crimp 2923 2915 2913

10 lb crimp 2915 2925 2906

15 lb crimp 2918 2916 2906

20 lb crimp 2907 2900 2901

25 lb crimp 2919 2905 2919

30 lb crimp 2915 2903 2915

35 lb crimp 2904 2903 2913 Most Accurate 0.54"

40 lb crimp 2907 2911 2916

45 lb crimp 2919 2909 2911

50 lb crimp 2920 2906 2905

ButterBean

Platinum Member

BC that's awesome , I'm glad it's working out you, How do you like the torque tool?

bc sportsman

Full Member

I like it because it seems to be idiot proof for people like me in the advanced stages of shooting and gun obsession related dementia and who want to spend their kid's inheritance.

mbruce

Platinum Member

I'm a sucker for gadgets. Today I bought a ball micrometer with a spindle turned down by LE Wilson. It'll measure necks just like the 2 other ones. Maybe my kids will reload.

bc sportsman

Full Member

One can only hope the kids carry on with at least some degree of interest. One of my two sons does. The other is too busy keeping me supplied with grandkids.

shinbone

Junior Member

bc - very interesting results and thanks for posting!

farleg

Platinum Member

Come on bc your tlkg about me as I need idiot proofing

Thanks for posting info great stuff

& go enjoy your SKI holiday stuff

cheers

jakesch

Senior Member

Well I just ordered lee crimp dies for my 6.5 PRC and 300 WM...I guess I will be jumping into this soon. Will probably read and re-read this post once I get them.

rausch

Senior Member

I’m currently building a 33 nosler and contacted Lee about a FCD. The response I got is it could be done but they aren’t taking any custom orders for the foreseeable future. Is there another way to accomplish what the FCD does? I’m planning on running the 235gr HH and the dummy round I seated already seems like it will need some sort of crimp to stay seated to the proper depth. I have not used a crimp die in the past so this is all new to me as are the Hammer bullets. Any suggestions?

ButterBean

Platinum Member

Let me take a look and I'll get back with you

ButterBean

Platinum Member

I think we can use a 338 RUM FCD, I'll need the die and a couple of pieces of dummy loads so i can modify it

rausch

Senior Member

So just to make sure I’m on the same page I should buy a 338 RUM FCD and send you a couple dummy rounds? I will still have to figure out OAL length I want to load first correct? The rifle is nearly done but I don’t have it in my possession yet.

ButterBean

Platinum Member

I just need the 338 RUM FCD die and 2 pieces of correctly trimmed brass with bullets in them

bojo34

Full Member

Thanks for the tutorial on Crimping BB. Going to give it a shot but a couple questions for experienced crimpers on this sight:

1) does crimping increase pressure all else equal? Just wondering if I should just add a slight crimp to my established load, which is 1gr under first signs of pressure, or if I should back down a bit on powder when adding the crimp?

2) I have not been in the practice of measuring neck tension, just use a standard RCBS FL resizing die. Would it be futile to just add the crimp without also measuring neck tension? Obviously optimal to do both but for those of us under time constraints and wanting to keep things as simple as possible thinking a crimp alone would still probably help, no?

bc sportsman

Full Member

Hi Bojo34, I defer to BB on most things related to shooting. However, while waiting for his response, take a look at data at the top of this page. I posted velocity changes with changes in crimp pressure and keeping neck diameter (4 thou) consistent. Best to read my results on a wider screen because of number of columns.

ButterBean

Platinum Member

Hey Bud, Yes it will increase pressure ( Look at BC's post ) and yes just adding the crimp by its self will help

mcd

Senior Member

Adding the crimp does not necessarily increase pressure. In fact, if the powder you’re using is slightly too slow, the crimp will actually lower pressure. In order to know this for sure, you’d have to have pressure sensing equipment. Resultant velocity alone does not tell the whole story. As far as neck tension, I personally prefer the standard .002” with a strong crimp. It doesn’t mean it’s right, but from what I’ve seen in pressure curves, it results in a positive initial ramp, with a flatter, lower pressure peak that is more consistent. Fine tuning for optimal barrel timing can be tuned through the crimp strength, up or down a little, but I always start strong. Tighter neck tension, in my limited testing, has proven to be peakier, and less consistent shot to shot.

ButterBean

Platinum Member

I've never had a crimp lower pressure and I mean no offense but I just don't buy in to all the pressure curves and strain gages , I always start with the lightest crimp possible and work up, I appreciate all the information but to much information takes the fun out of it for me All the graphs and printed paper information make the Needmoor untouchable but in the end its just a piece paper once again no offense

mcd

Senior Member

No worries. You’ve fine tuned your process over the years, and it works well. I could probably guarantee you your pet loads would look very good on the PTII because of all the care and precision you do in development. As I mentioned, my testing with the system is somewhat limited in sample size as all the work has taken place relatively recently, but it is what I’m seeing for certain scenarios. I need to add that with the strong crimp, I always seat far off the lands on purpose. Those two go hand in hand. How I develop loads now is ensure a clean, consistent pressure curve. From there, it’s usually very easy to settle on a node. 100% of those combinations shoot on top of each other with a very low ES. Sample size is small, relatively, but the trend is unwavering. I find myself shooting far less development loads to get to pet recipes.

carsyn22

Senior Member

That's a bunch of great info!

ButterBean have you ever messed with a 25-300 win mag? No particular reason, I just saw some brass for sale here in SK and thought of you with your affinity for 25's and speed that must be a screamer.

that must be a screamer.

bc sportsman

Full Member

Hi mcd, i have both a 2.5 thou and 4 thou neck size mandrell from K&M Precision. I was using the 2.5 thou for Barnes but switched to 4 thou with Hammers based on how slippery these are and Steve saying in one of his posts that he sometimes doesnt bother expanding the neck after FL sizing. However, at the time of Steve's post, he wasnt taking into account doing any crimping to tune.

I now always use the Lee FCD, thanks to BB's thread on this. I was successful varying crimp pressure to tune the load based on input from Butterbean, you and other very knowledgable guys and got my groups to noticeably tighten.

Based on your and BB comments above, I'm guessing I should use my 2.5 thou mandrell, rather than my 4 thou, and then fine tune OBT by increasing crimp pressure from light to heavy. I would find it easier to go in one direction re crimp pressure as per BB as opposed to starting somewhere in the middle. My personal preference just in case the optimum crimp pressure is on the light end.

Id appreciate your thoughts and thanks for the insight on neck tension.

mcd

Senior Member

Your approach seems good to me. For me, I always prefer to keep the bullet in place due to recoil, so I tend to want to keep it in place with a tighter crimp for that reason. My favorite rifle, my NULA 300 WM, is very light and kicks very fast. It’s pretty tough on bullets staying put. My methods bend around its propensity to dislodge bullets. It’s worked very well, so I’m adopting that approach to everything. The key is getting consistency from the beginning of the burn cycle and ending on a favorable barrel node for ultimate precision. No doubt several methods can achieve that successfully but utilizing different paths.

farleg

Platinum Member

Gday mcd

Ok guys time for the idiot taswegian to get on board & work this out as I believe this is extremely important & especially for new reloaders As my first concern is safety as I’m sure everyone is

First off this is me

I work up loads from a loading manual ( yes old school still ) start @ start load & work towards max then I push the limits if no pressure was found

Now move to FCD

The lee docents say It’s best to start with a Little crimp & add more just like the reloading manuals ( see attached pic )

So in conclusion I may be reading / interpreting this wrong ( which does happen)

Bojo34 has asked for clarification & to me I’d start a bit low again ( Maybe his 1 gr is sufficient I don’t no ) (Just like in manuals & FCD ) . Is this correct advice ?

Now I’ve got no pressure gauges so i look for pressure signs

So could you please explain with all being equal how can you get a strong crimp to give less pressure vrs a light crimp giving more

I’m not having a go as what concerns me is if someone else interprets like me

Eg I’ve got a slow powder with no or little crimp that’s got pressure so I’ll just go give a strong crimp ( that could be fully crimped for some ) & pressure will be reduced so I’m ok

Me personally I think that’s a very dangerous Scenario & why I’ve given my 5 cents on this

No offence intended just want clarification & safety first

Cheers

bc sportsman

Full Member

Hi mcd, can u please clarify what u mean when u say tighter neck tension results in peakier pressure curve.

Are u saying that about a load that solely relies upon heavy neck tension due to case neck diameter, say 4 thou, without any crimping?

Or...

Are u saying that the steeper curve ALSO happens when u combine heavy neck tension and a crimp?

I wonder if the presence of even a light crimp might act to negate the effect of heavy neck tension.

This is way above my lowly pay grade to figure out so appreciate hearing from all who have insight.

ButterBean

Platinum Member

ButterBean have you ever messed with a 25-300 win mag? No particular reason, I just saw some brass for sale here in SK and thought of you with your affinity for 25's and speed that must be a screamer...

that must be a screamer...

No I have not, The biggest 25 cal I've done so far is the Hot Tamale ( 25 STW ) but I have seen something new that hasn't been done yet and has sparked my interest and has my ticking as Farleg would say and I'm studying hard on it

mcd

Senior Member

Farleg and bcsportsman,

The 1/2 turn crimp, as suggested by Lee is actually a pretty hefty crimp. It’s where I start though. It can go higher, but not too much. However, I’ve never had to yet

In answering the neck tension question, a tighter neck without the crimp has shown an increase in the burn rate of the powder used significantly. The curve climbs faster all the way to the top. This is with such a small sample size, but the effect was so significant, I completely avoided it any further. In some cases, that may be needed or desired and potentially, the behavior could be different. In the instance I was looking at, it definitely wasn’t as the powder was the right burn rate from the start. For whatever reason, the crimp loads differently. It surges up to between 5-10 ksi then flattens out at release with the bullet continuing forward on a gentler slope up. If done correctly, all bullets share the same time curve up front

The reason I say a slower powder without a crimp may actually have a higher pressure relates to the beginning phenomenon of using a powder with too little charge weight which is an extreme case. The resultant curve looks to like it has a slight hang fire, then it sweeps upward hard. In factory load examples where a light crimp created a delay versus the others, that load started late, had a lower velocity, and a peak pressure maybe 250-1000 psi higher than the other loads.

Remember, our loads are a complex relationship of individual contributions convoluted with interactions. So many things can change different aspects of the burn cycle. What I’ve found has worked so far in every instance, albeit only a few.

mcd

Senior Member

Let me add one thing as I missed a point by farleg. I would always throttle back a hair on powder anytime I make a change. Way better to be safe and burn a few more rounds than be sorry. I don’t even know how I failed to mention that.

A bit more color on the tighter neck tension with crimp. I have not done that specifically yet. That’s what butterbean does, and has laid out in this post, and has proven successful for him for quite a while. Very hard to argue against that.

The reason I stick with the .002” normal interference fit is because I’m able to manipulate anything I need/want with the crimp die. It’s the discovery path I took when incorporating the PTII, and it’s been rock solid so far. It’s way easier to manage due to normal dies being able to be used in their entirety, and bullets aren’t damaged during seating.

mcd

Senior Member

Now that I'm on my computer and not on the phone, here's an example of two factory rounds. Notice the green one that clearly had an inferior crimp to the blue one actually has a slightly higher end pressure. The velocities for both were almost identical at:

Blue - 2998 fps

Green - 3000 fps

You would think these would shoot tight based on the ES, but they did not, of course, based off muzzle exit times.

bojo34

Full Member

Thanks all....great information. I was likely going to back off on powder charge in the sprit of conservatism anyway just curious on people's experience with crimping's affect on pressure. Did scan BC's table but, again, curious if anyone else had seen different results. As noted anytime a component/process to load workup changes it would be prudent to affectively start the process all over, which is what I will do.......certainly should make Steve happy! Currently under a foot of fresh snow here on the east coast so will likely be awhile before I can report back with progress.

Cheers

ButterBean

Platinum Member

If you have a load that's shooting good but needs improvement that's where I would start but that's just me

farleg

Platinum Member

Gday mcd

Think I understand & that’s all to do with harmonics which can be adjusted so simply with a crimp as one of the principals like powder charge , primer, projectile with good brass

& that’s all to do with harmonics which can be adjusted so simply with a crimp as one of the principals like powder charge , primer, projectile with good brass

cheers

mbruce

Platinum Member

I might be off but I look at it like this: Neck tension grips the bullet with friction. Crimp grips the bullet by indenting. They want to achieve the same result.

The less bearing surface touching the neck, the less friction. The less friction the faster powder you may need.

Crimping is a polarizing topic because mostly Lee is the only one producing a rifle crimp die. Also, few —in the grand scheme— shoot bullets with small bearing surfaces. So the crimp die is unfamiliar to the majority. In the Hammer world the majority might be wrong. But it is reasonable for most reloaders to be skeptical

ButterBean

Platinum Member

Your spot on, I was using the Lee FCD long before Hammers were around with great success , and yes the Hammer really responds to it but there will always be the nay sayers, on the LRH forum one of the greatest guys there and renowned gunsmith JE Custom finally got curious enough and did a test for himself, the results surprised him, do you need to crimp ???? Nope, folks been shooting along time without crimping, I've been shooting a long time and I crimp everything and I have never seen any disadvantages if done correctly

littlebighorn

Full Member

Well ButterBean, I just gave two Lee FCDs to my wife to give to me for Christmas.

I hope she's not disappointed!

ButterBean

Platinum Member

I'm sure she'll love em

farleg

Platinum Member

Well my first FCD showed up today in 6.5 grendel. So naturally I ordered some 99gr HH to try today as well. I’m really excited about the potential of this combo in my suppressed AR. I’ve got a crimp die on the way for my .300 WM but haven’t settled on which bullet to try in that setup yet. I currently shoot 180 AB’s but I was thinking of dropping weight a little there because my custom .33 nosler is done and I’ll be shooting a heavier bullet out of that setup.

Gday rausch

I like & why your thinking lighter I couldn’t help but put my bit in

why not go to the 137 out of the 300 wm & get them cranking

within a 400/500 range no animal would walk away from those

cheers

carsyn22

Senior Member

I also asked for a FCD in 300wm for Christmas! Thing is though, if I don't get it then I will just go buy one HAHA!

rausch I agree with going light and fast in the 300wm, as you mentioned you have a .33 for heavy, I went with the 178 AH only because it was the first AH available when I ordered and I didn't want to wait any longer, but the 151 AH would get more speed. Or like Farleg said the 137 might be worth a good look too!

All the best and Merry Christmas!

farleg

Platinum Member

Gday carsyn22

i heard a rumour that Santa only comes to good kids lol so we all should get what we’ve asked for

i dont disagree & good pick up with the 151 ah as overall it would be extremely hard to beat it covers a lot of bases & my thinking is you should be able to get a 151ah to around the same speed as the 137 hh

so I’ll have 2 bob ea way

as I see it & if rausch is comfortable loading for the ah go for that if not the 137 hh

merry christmas

cheers

riceman

Global Moderator

Those 137’s can really GO in a 300wm

I have them going @ 3500 in a win 70.

Using 4955

rausch

Senior Member

And that might be another problem. I don’t have much for faster powders for the light bullets right now. Been running H4831 so I have plenty of that and some slower powders.

riceman

Global Moderator

Imr 4955 is very similar to h4831. Check out burn rate charts and you will see they are right next to each other. Your h4831 should be fine.

carsyn22

Senior Member

H4831

That's exactly the powder that I'm using in mine with the 178's, I'm seating them out to 3.620 so it's single shot only at this point, I might figure a way to have one down and one in the pipe with the new stock I'm making.

Anyway I am using R-P brass which is pretty soft it seems, I have got up to 81 gr in those cases without spring back and that's no crimp yet as I'm still waiting for Christmas! I loaded the 81gr over a week ago and it is still the same OAL so it should be fine with a crimp, then I will see if it hits pressure, 80 was good but definitely getting close for this brass and gun.

For the 151AH I would probably start with H4350 or similar, not the newest or fastest powder around but it's a proven performer, and more important it's available, at least around here.

bojo34

Full Member

First attempts crimping with Lee FCD today. Not crimping for accuracy yet trying a new powder ladder so wanted to start with a middle ground/base line crimp for purpose of finding pressure. Started with a 1/4 turn crimp (below shell holder as per Lee instructions) and felt no resistance from ram arm. Tried again with a half turn crimp and only felt very slight resistance at the very last instance of ram’s travel.

Does this sound right? Is there virtually no discernible resistance with a half-turn crimp or am I improperly set up?

Thanks for guidance.

ButterBean

Platinum Member

Don't use the Lee Instructions

bojo34

Full Member

Got it, Thanks. Actually read this a couple of weeks ago but when the Crimp die showed up still went to the instructions....too eager to try it out!

carsyn22

Senior Member

Lee's instructions aren't very specific, I did it their way for a while, but now I just raise a loaded round an the ram and then screw the die down by hand until it's hand tight then mark my 1/8 and 1/4 marks from there, if you want to jump straight to a decent crimp that will probably work ok then I use 1/4. For cannelured bullets used in a tubular mag I like a little more if they'll shoot well with more.

bc sportsman

Full Member

I just experimented seating and crimping 162AH bullets in 308 Win Lapua brass. I seated the test bullet in an empty case (with a neck tension of 4 thou) to the point where I "thought" that the end of the brass neck was right at the bottom of the valley of the last PDR cannelure. The COAL was 2.878". I then used my Consistent Crimp tool set at 15 in/lbs. The COAL shortened to 2.868" after crimping. I then adjusted the Consistent Crimp to 20 in/lb, re-crimped the same cartridge and got 2.867", repeated at 25 in/lb = 2.8665", 30 in/lb = 2.866", 35 in/lb = 2.8655", 40 in/lb = 2.8655", 45 in/lb = 2.8650", 50 in/lb = 2.8645".

Its important to note that I didn't use new brass case each time, just re-crimped over top of the previous crimp at a higher pressure. The next question that I needed to settle was whether the continued shortening of COAL was due to the cumulative effect of multiple crimping of the same cartridge.

I used a new brass case and seated that bullet to 2.868" COAL, which is the shortened COAL from my first test crimp at 15 in/lb. I then only made one crimping at 50 in/lb and discovered that the COAL barely shortened to 2.8675". I'm guessing that what happens is that the first crimp moves the bullet to its optimal position in the valley of the PDR cannelure. Re-crimping the same bullet moves the bullet a tad more each time. I'm guessing that it will eventually settle down. However, what is important is setting your COAL to that first crimp measurement.

I'm suggesting that you determine your COAL for crimping by seating your test bullet so that the end of the case neck is in the middle of the PDR cannelure valley, then set up your LEE FCD for a fairly strong crimp. Re-measure your COAL after your crimp and adjust your bullet seating die to that measurement when doing live round loads.

Since you will only be crimping each loaded round once, you should use the first crimp COAL as your bullet seating COAL. You also need to have a consistent case trim length.

Has anyone had a different experience or differing advice?

ButterBean

Platinum Member

I thought this might be of interest Before and after a 1/8th turn crimp

mcd

Senior Member

Cool pics. That looks a lot like my “half turn crimp setting. You must really crank it down manually before turning it further. I just manually turn it to touch the deck, then do a half turn after that. How did you even take those? Very neat.

ButterBean

Platinum Member

I do not crank it down, That is a very light crimp

jasperhayduke

New Member

This is another awesome thread! After reading the whole thing, I feel like i wanna crimp. I mean why not? Especially since I’m just at the beginning stages of working up Hammer loads for 2 different calibers.

BUT of course now I can’t find Lee FCD For 7/08 or 300wm anywhere. ARG!

ButterBean

Platinum Member

I'll see what I can find

jasperhayduke

New Member

Oh awesome. Ya, if you may know a source for the dies, I’d love to know!

Also Thank you for all the valuable info you’ve provided on this and other threads!

(extended conversation around looking for FCDs omitted)

tgr

New Member

Ok. Need some help. Working up a load for a new Christiansen Mesa in 308 win. Im new to Hammer Bullets but have been reloading 15 years. After break-in I spent a few sessions shooting ladders with the Hammer Hunter 152 and Hornady SST 150 grain. With both I reached subtle pressure signs about 47.ish gr of TAC. I settled on 46.0 TAC, CCI LR Primer, Winchester Brass and 2.80 COL for the Hammer and 2.75 COL for the SST. All was great, with both loads shooting 0.5 MOA out of the Mesa around 3000fps with NO CRIMP. Velocity Devs were low double digits (13fps)for 3 shot groups

I don't usually crimp my 308 bolt action rounds, but after reading this thread, I decided to crimp them both and see if I spotted any differences.

The 152 Hammer dropped to 2670 fps (-300 fps) but maintained single digit deviation and 0.5 MOA.

The SST boosted up to about to 3060 fps but devs increased a bit. Group still 0.5 MOA

What am I missing? Could the crimp make that much of a difference for the Hammers where I need to run a new ladder again?

One thing Ive considered is the SST has a cannelure and may provide more consistent crimping. The hammer was crimped just past the top of a band because the COL was already established. I will try a crimping with a slightly different COL to match up with a valley and see if helps.

Possibly a chronograph issue while checking the Hammers?. Day 1 was giving me fits cause of lighting, but I definitely trust the numbers for day 2. Can anyone verify with Quickload for me? (22 inch barrel, 82 degrees, sea level)

These are hunting loads for a fairly lightweight rifle, so Im ok with my original setup, but Im always looking to learn more. Ideas? Thoughts?

ua26fitter

Full Member

Tgr

Frustrations with my old chronograph working sometimes and not others and not sure if you can trust the info is what drove me to purchase a Labradar.

It's so simple to use and you always get good info.

I'm not sure how you would lose that much speed from crimping. That doesn't sound right at all.

Kris

ButterBean

Platinum Member

I'm gonna say you have Chrono troubles

antelopedundee said:

One issue I see if trying to use a crimp be it FCD or the crimp in your seating die is that for the 6.5-06AI your cases will likely be too short if you made them from 25-06 cases. When fire forming into AI cases, the new case will be .012 -.015 short and they don't grow much if at all after that.

ButterBean

Platinum Member

280 or 270 brass cures that problem

jakesch

Senior Member

Okay after a busy 8 months, I am finally setup to start crimping. Going to we-work load development since I got the FX-120i with v3 autotrickler.

My main question is, do you do a full ladder with each crimp setting? Or do you narrow down the charge range as you increase crimp since the first ladder should get you a close idea. In addition, if I already have loads developed...should I just go plus / minus a grain (in half grain increments)?

I appreciate the knowledge sharing!

ButterBean

Platinum Member

Do you have a load worked up already?

jakesch

Senior Member

I did, but I just replaced the stock on both my 300 WM & 6.5 PRC so my guess is I will need to do a little fine tuning and got my v3 autotrickler system setup. Figured it was a great time to bring the FCD into the process.

bjornf16

Full Member

Lee doesn’t make a 6.5 RPM FCD, so I’m using a 26N FCD. The RPM case is just a little short.

What’s the modification I need to make?…shorten the inside sleeve at bottom?

ButterBean

Platinum Member

Send me the die and a dummy round and I’ll fix it for ya

hawkpilot81

New Member

I am now a believer in the Lee FCD. I have a .5 MOA load worked up for my 7mm Rem Mag with 67.3 grains of H4831sc and the 143 HHs. Just hit some with a 1/8T and it’s now a .25 MOA load. Didn’t think it would work honesty.

ButterBean

Platinum Member

That's awesome

jer2170

New Member

Love the Lee FCD.Honestly a fan of their neck collett dies as well. I use a mix of the Lee neck sizer, Redding body die to bump shoulders, and a FCD to finish things off. All set up to toggle over in a 30+ year old Rockchucker.

Tested run of 5 7-08 120gn HH couple days ago. 48.0gn CFE223(1gn. below pressure in my rifle)once fired Lapua brass, CCI200. 3/16T FCD crimp per Butterbeans method.3164fps avg. ES-3, SD-1. Small sample size I know, but representative of what you can do with FCD.

kyboo

New Member

Thanks ButterBean, I had been trying to get my Savage Ultralite in 280AI to shoot the Hornady 139 SST’s. I couldn’t get anything better than a 1 1/4 group at a 100 yards. Tried crimping after reading a few of your post. The rifle is now shooting 1/4-1/2 at a 100 yards. I followed your directions and you are right, it doesn’t look like it is doing much but it does. Thanks again

kimber7man

New Member

Does Lee make a FCD for 6.5 SAUM and 7 SAUM? Didn’t see that option on Midway’s website.

Thanks!

gltaylor

Global Moderator

Not presently, but i bet the 6.5 PRC would work. That's what I'm using for my 6.5 Sherman MAX.

Don't know about a 7mm.

redside

New Member

Interested in the 7SAUM as well. I contacted LEE as they can make custom dies. Currently the custom shop is down.

ButterBean any thoughts on what die would be compatible with the 7SAUM? Thanks!

ButterBean

Platinum Member

I can modify one for you, I charge $70 and will need a dummy round

tthetinkerer

Senior Member

BB,

You've been championing the Lee FCD for a while and I just wanna say keep it up. I've been using it since day 1 of reloading and have never got better results without it.

ButterBean

Platinum Member

It's just a shame that folks have been brainwashed and are missing out on all of the benefits it provides

windypants

New Member

I tried the butterbean crimp on 184 bergers in 28 nosler today. I shot a 5 shot group from a -.002 bushing die without a crimp, and then same die but with 1/8th turn crimp(@300 yds.).

no crimp: ES - 86

ave. fps- 3017

vert. disp. - 1.75

w/crimp: ES - 32

ave. fps - 3039

vertical - 1.25

POI - +1.0 higher

I'm impressed--can't wait to test some more!

z987k

New Member

So what are people doing for crimp on cartridges that lee doesn't make a FCD for?

gltaylor

Global Moderator

All you can do is look at the parent cartridge and look at cartridge drawings to get dimensions to see if they'll work. For example, a 300 PRC fcd will work for a 30 Sherman mag, or a 25/06 will work for the AI version. Otherwise, you can get someone to make a shim spacer that goes over the case to make it the right height for the fcd.

bjornf16

Full Member

gltaylor Man that eggnog still has me seeing double...lol

I don’t think it has to be parent cartridge. Any FCD in same caliber of longer case length can be modified for the shorter case. ButterBean has done two for me now...he’s currently turning a 7 STW into 7 Wby FCD.

gltaylor

Global Moderator

Yep, he's done some wildcats for me as well. He's the "someone" I was referring to. Just didn't want to obligate/bother him

ButterBean

Platinum Member

It's never a bother, I'm always glad to help

z987k

New Member

Ya, I don't have a FCD in the correct caliber to test this, but it seems like if the case will fit inside the die body, you could just adjust how deep it goes in there to get it right... maybe not.

I'm in need of one for a 338sherman max I'm having a barrel done for. Would the 338wm or 338lm die work?

bjornf16

Full Member

Doesn’t quite work that way. There is a sliding sleeve pushed up by the shell holder. That has to be correct length per cartridge length to properly crimp.

gltaylor

Global Moderator

That is correct. The "sleeve" i referred to is the piece that Butterbean made for me. Your die has to match the general dimensions of the cartridge. The "sleeve" is a height adjustment to make the collar crimp at the correct height for your cartridge case length. The sleeve goes around the case and fits between the shell holder and the bottom of the FCDie.

z987k

New Member

Ah ya, I got my 30-06 one and I'm actually looking at it. Ya, it'd have to be custom done.

choprzrul

Junior Member

I'm just clarifying.....the top of the case mouth should center in the middle of the top groove in the bullet?

.264 85gr HH.

Left blue tick mark is trying to show the bottom of the top groove:

Are you able to see visible crimping marks on your brass? Can you see it squeezed into the top groove? I'm just looking for points of reference.....

riceman

Global Moderator

This will give you a good close up.

This being example of 25-06 with 75hh.

This is about 1/4 turn

Alan

ButterBean

Platinum Member

Yes and yes (post above)

kneedeep

Full Member

I think ran into some of the Lee FCD adjustment issues some of the members were asking/talking about. I was crimping my 270win load (117HH) for the first time. I'd set the die for 1/8 turn. At the top of the stroke I notice the bullet appeared to have some play in it. This bullet sticks out of the top of the die a reasonable amount. Looking down from the top, I raised the round all the way to the top again and watched the collet closing. With the collet closed, as much as my setting allowed, I grabbed the bullet with thumb and finger. I could easily spin the entire round in the die. It wasn't making any contact.

I started adjusting the die in further and checking for contact. It took 3/4 of a turn to make initial contact.

Pic above shows how far the collet is closed on 270win to make first contact with the round all the way at the top of the stroke.

Pic above shows the 270win round raised into die but collet fully open for reference.

Pic above is the resulting crimp with the collet fully closed.

I had also loaded some 124HHs in my 308win. The bullet doesn't stick out the top of this die so I stuck one finger down in the die to touch the point of the bullet. I could wiggle it with die adjusted 1/8 turn and the ram at the top of the stroke. It took 1/2 turn to get the collet to make contact with the round, no wiggle.

Pic above shows how far the collet is closed on 308win to make contact.

Pic above shows resulting crimp on the two hammers on the left. No crimp on the two hammers on the right. I couldn't see or feel any difference of the 1/8 turn crimp.

Bottom line, I'll be checking for a starting point for each FCD from now on. Also, with this much variance in adjustment from die to die, I'll be buying lock rings for the dies so the crimp is the same every time.

kneedeep

ButterBean

Platinum Member

You are crimping in the wrong place, you are still on the PDR band which will move the bullet down as you crimp there is a video and pictures a way’s back in this tread showing where the crimp should be And that’s also a very heavy crimp

kneedeep

Full Member

Ok thanks. I'll look at it again.

Is riceman's pic about two posts up correct?

I did measure the overall length after crimp and it didn't change.

The issue was in setting up the die to get a crimp at all. I tried your method for initial die setup from your video. I was not getting any contact with the collet on the case mouth. I likely didn't explain it well.

I have used the FCD on a 300PRC/214HH and it worked per your instructions. These 270 and 308 dies did not.

I will however look at the location again as I see your point.

Thanks

kneedeep

riceman

Global Moderator

My pic of the 25-06 could of had the bullet a touch deeper. But not much..

Your 270 could be the same slightly deeper.

Your 308 win a little too deep.

I try for a area just above deepest part of groove.

kneedeep

Full Member

Thanks riceman

My post was originally intended for setup of the dies but I put too much info in and didn't explain well.

With that said, I definitely don't want to be too close to the PDR band to change COAL. So, thank you and butterbean for pointing it out.

The 308 rounds were not intended to be crimped in a PDR valley. I wanted to see what the outcome of velocity and max load was by having three PDR bands (124HH) for more surface contact in the neck. Then basically crimping over the ogive.

Thanks again

kneedeep

kneedeep

Full Member

ButterBean

Thank you for responding as it motivated me to revisit the 270 and 308 FCDs.

The 308 die is several years old with no use other than when I first purchased it. The collet inside the body is very stiff. I oiled and worked the die several times. It is still stiff. Maybe more oil and work will loosen it more. I believe this stiffness is what makes it feel like the collet is touching the case mouth. I still can not adjust the die by hand without lowering the case out of the collet. The collet is not close to the top of the die so it is difficult to see.

The 270 die is relatively new and this was it's first use. Luckily the collet is very close to the top of the die body so I could see what was going on.

With an empty, sized case I raised the case into the FCD and proceeded to adjust it according to your instructions. What felt like the collet making contact with the case mouth was not what was happening. I lower and removed the case, then oiled the collet. I adjusted the die so the collet was almost completely closed, then worked the collet in the die using the ram and shelf holder. This resulted in the collet moving more smoothly when closing. I can only assume this die needed some "break in" so I could "feel" the collet contact case mouth and not the rough spot I was feeling before.

I loaded a dummy round to see if this die would reproduce a similar looking crimp (depth) to riceman's 1/4 turn.

The above pic is a 270win crimp with the collet fully closed. Max crimp. Which is roughly a 1/2 turn past the collet making contact with the case mouth.

A 1/4 turn results in no visible sign of a crimp, although I realize it is crimping. It does not look like riceman's 1/4 turn crimp to me.

Thank you for the response, as it helped me see what was going on with the feel factor.

kneedeep

ButterBean

Platinum Member

cbjr

Senior Member

I have found crimping them the way Butterbean's pictures show also help stop seating depth changes to cartridges loaded in the mag. But that is just an added bonus!

ButterBean

Platinum Member

Before I open up the age old argument of to Crimp or not to Crimp I just want to say this is my process and it works for me ,I'm not trying to push it on anybody or saying that what anyone is doing is wrong, I love reloading and I have spent a small fortune on the latest and greatest and 30 years later I have come full circle and am almost where I started finding I can do a lot with a little. Anyway The Lee FCD, It comes with instructions and they work fine set to those specs but here is how I use it to "Fine Tune", Back the die way off and raise a round, screw the die in until it tightens up against the round, (Hand tighten really snug and I take a fine line sharpie and mark the die, lock nut and press at this point for reference), lower the round and give it a 16th to 1/8th or so of a turn, ( I prefer to cam over doing this with the Rock Chucker press so I know I'm consistent ) it may not look like it did anything but I assure you it did, crimp a string of however many you want and see if it helps, if it didn't give it another 16th to an 1/8th of a turn in and repeat. You can take bigger swings if you like but I don't .The way I use the Lee FCD its the same as finding a powder charge or seating depth. Once again I'm no professional and I'm not a competition shooter I'm a hunter who loves fast accurate rifles and this works for me and i use it on everything I load for, I have seen it help various calibers and I will say that I personally have never seen it hurt one in any way, The problem I was having with the 30 Cal 124 was lack of baring surface in the case neck, The FCD equalized things providing a more consistent initial burn and bullet release time, and I made a big gain in everything and I mean big, I will say that in my load development with conventional bullets this was the last thing I did after establishing a load but in my short time of working with Hammer Bullets I would suggest to start with a light crimp from the start of initial load development for a known constant bullet release , The reason I started crimping in the first place is another story that I revisited last week because i was in a hurry and it came back to bite me ...... again but that's another story, I do a lot of unconventional things from the Case Lube or the Dies I like to use some folks think I'm crazy I reckon, Once again this is just how I do things, I just want to say this again so it doesn't get all twisted,

ButterBean

bc sportsman

Full Member

Thanks for this BB!

So do you suggest a light crimp when working up a first time load for Hammer bullets, then when you get good results, change seating depth to optimize, the play a bit by increasing crimp?

Or, increase crimp first to find a good place, then change bullet seating depth?

mcd

Senior Member

Butterbean,

Do you recommend disassembling the die and greasing it prior to use? Maybe even lightly debur the collet edges? I really wish Lee’s quality at the source was a lot better. I’ve heard a lot of folks just leave the burrs, and they don’t seem to hurt much other than scoring the case potentially, or maybe not, just depending on where they are.

I've not had any neck scoring with my Lee FCD loading for my 375 H&H mag. I use several compressed loads and this keeps the bullet from extruding (realistically that didn't happen before I crimped). My OCD side just wants to be sure! GJ

mcd

Senior Member

Just rechecked my FCD, and mine actually looks pretty good as far as finishing of the collets. It's my Lee neck sizing collet die that is heavily burred, also never used. For those that use the crimp die, based on the type of bullet and seating depth, I could see quite a bit of variation in the crimper's position, correct. This is not a one and done, but rather a specific setting per bullet selected, and in the case of the Hammers, seating depth too. Is that correct?

bc sportsman

Full Member

I have developed close to max loads in my two rifles.

Fierce 300WM,166HH,F215M,new GW brass, 79.0 gr R23,3358 fps

Sako Finnlight 20" barrel,308Win,152HH,F215M,new Lapua brass, 45.0 gr ARComp, 2918 fps

Im going to be shooting for groups by fine tuning using incremental increases in crimp pressure, based on Butterbeans good advice to me.

Will probably shoot later this coming week and will post results (change in velocity, grouping, bolt extraction, case dimensions).

ButterBean

Platinum Member

Bud I apologize as I just saw this and yes i disassemble and grease but I have never had any quality issues wit Lee Products

mcd

Senior Member

No problem. I had confused my Lee neck sizer (unused) with my crimp die. I’ve been crimping for a while now.

farleg

Platinum Member

All I can say is the biggest thing I like is how this fits perfectly in with the kiss system & that’s me through & through

Thanks & Cheers

mbruce

Platinum Member

mcd will like this...

Crimping is an alternative to bushings -- more or less.

The reason why neck tension influences precision is it impacts the pressure curve, ultimately impacting optimal bullet time. Your internal ballistics and barrel will heavily prefer a specific curve.

Here's Pressure Trace demonstrating variable neck tension effects: (Found here: www.shootingsoftware.com/recoil.htm)

mcd

Senior Member

Very cool! I think the two most significant pieces of equipment I’ve procured over the last couple years are the LabRadar and the Pressure Trace II. Between the two, so much useful information is available.

ButterBean

Platinum Member

Thank you so much, I have been trying to tell folks this for decades, I'm really excited over the graph

joliver

Full Member

Thanks guys! I just ordered dies for all my calibers it makes sense to me especially with hammers. My load development is on hold until my crimp dies come in

joliver

Full Member

I grew impatient waiting for crimp dies. Beautiful day and all. I had some .270 win’s loaded with 85gr shock hammers. I do believe I just saw on the chrono exactly what everyone who crimps is talking about!!!

joliver

Full Member

All varying charge weights looking for pressure. From 55-58 the last one was 58.5.

as you can see velocity hits it’s high at 57gr. Then proceeds to drop off at 58 and 58.5. I feel like I’m loosing velocity due to improper powder burn because of no crimp. Grouping was all touching each other. Thoughts!?

ButterBean

Platinum Member

It'll help it

cbjr

Senior Member

Ok, Question. Where, on the hammers, do you crimp? After the pdr section, on the high spots of the pdr, or in the valleys between? Could it be I'm just reading this wrong and there are multiple places to do this?

Thanks

Edit: How much neck tension do you use vs. no crimp?

joliver

Full Member

Just saw this sorry for the delayed response. I'm new to this as too. but i plan on just running it through the crimp die as Bean described. I did this over the weekend. I honestly can't tell a difference by looking at the neck. I haven't measured but i could hear an audible squeak as i ran the loads through the die. I didn't pay much attention to where i crimped it was just where ever they were seated but my loads do appear to be right on one of the valleys. Just coincidence thought.

ButterBean

Platinum Member

.003-.004 on the neck tension and crimp in the valley is what I have been doing

cbjr

Senior Member

Thanks for the clarification, BB!

mbruce

Platinum Member

Would die shims be useful for the FCD....I'm thinking about absolute repeatability when toying with adjustments. May be overkill for its application...but so is 90% of reloading. ha

benchrite.com/skips-7-8-14-sizing-die-shims/

ButterBean

Platinum Member

It would just be another way to fine tune it, It probably is overkill but who knows, I'm always willing to learn something new

shinbone

Junior Member

bcsportsman - maybe I missed it, but have you posted any results from your testing, yet?

bc sportsman

Full Member

Here is my data on both my 300WM and 308 Win using two different powders for each. I used Redding Dry Lube when seating bullets and neck tension was 4 thou for both cartridges using K&M expander mandrell.

My best group for 300WM turned out to be 79.0 gr of R23 at 10lb crimp pressure using the Consistent Crimp tool from Titan reloading. I did test loads with 5 and 10 lbs just to see what effect they had on velocity. I haven't had the time to play with different crimp pressures to fine tune my 300WM best accuracy load which was 10 lb crimp of 79.0 gr R23. Hope to do so later this month.

I also saw no signs of excessive pressure on brass and couldn't tell if the bolt extraction changed. Bolt extraction never seemed "hard" with any loads but may have progressively increased without me noticing. I measured the length of the GW 300WM fired brass. Brass was 2.610 - 2.612" before firing.

I tested various crimp pressure for my 308Win. 35 inch/lbs gave good group, about half the size of the rest which were from 1" to 2". Amazing how they settled down at 35 lbs, then opened up again.

Fierce 300 WM (MAX COAL 3.58": COAL 3.49": CBTO 2.797": Case Length ~2.611")

166 HH, Fed 215M Primers, New Gunwerks Brass

Crimp = 5 lb Crimp = 10 lb Case Length After Firing

R23 75.0 gr 3215 3208 2.6175

R23 76.0 gr 3246 3278 2.6150

R23 77.0 gr 3263 3295 2.6175

R23 77.5 gr 3303 2.6175

R23 78.0 gr 3326 2.6140 Online Data Max

R23 78.5 gr 3352 2.6145

R23 79.0 gr 3364 2.6150

1st Shot 2nd Shot 3rd Shot 4th Shot

R23 10 lb Crimp 77.0 gr 3304 3288

R23 10 lb Crimp 78.0 gr 3333 3333 3325 3340

R23 10 lb Crimp 78.5 gr 3372 3344 3348 3359

R23 10 lb Crimp 79.0 gr 3362 3370 3365 3360 Most Accurate 0.6"

Crimp = 5 lb

R16 68.0 gr

R16 69.0 gr 3054

R16 69.5 gr 3122

R16 70.0 gr 3126

R16 71.0 gr 3170

R16 71.5 gr 3179

R16 72.0 gr 3218

R16 72.5 gr 3271 Online Manual Data Max

R16 73.0 gr 3266

R16 73.5 gr 3286

Sako Finnlight 308W (MAX COAL 2.828": COAL 2.7673": CBTO 2.1685": Case Length ~2.010")

152HH, Fed 215M Primers, New Lapua Brass

Crimp = 5 lb

XBR8208 40.0 gr 2571

XBR8208 41.0 gr 2649

XBR8208 41.5 gr 2670

XBR8208 42.0 gr 2695

XBR8208 42.5 gr 2717

XBR8208 43.0 gr 2748

XBR8208 43.5 gr 2789

XBR8208 44.0 gr 2825

XBR8208 44.5 gr Shot not recorded Online Data Max

XBR8208 45.0 gr 2855

XBR8208 45.5 gr 2891

5 lb crimp No crimp

ARComp 41.0 gr 2728

ARComp 41.5 gr 2745

ARComp 42.0 gr 2757

ARComp 42.5 gr 2768 2796

ARComp 43.0 gr 2817 2805

ARComp 43.5 gr 2839

ARComp 44.0 gr 2873 Online Data Max

ARComp 44.5 gr 2895

ARComp 45.0 gr 2919

AR Comp 45.0 gr

0 lb crimp 2918 2914 2915

5 lb crimp 2923 2915 2913

10 lb crimp 2915 2925 2906

15 lb crimp 2918 2916 2906

20 lb crimp 2907 2900 2901

25 lb crimp 2919 2905 2919

30 lb crimp 2915 2903 2915

35 lb crimp 2904 2903 2913 Most Accurate 0.54"

40 lb crimp 2907 2911 2916

45 lb crimp 2919 2909 2911

50 lb crimp 2920 2906 2905

ButterBean

Platinum Member

BC that's awesome , I'm glad it's working out you, How do you like the torque tool?

bc sportsman

Full Member

I like it because it seems to be idiot proof for people like me in the advanced stages of shooting and gun obsession related dementia and who want to spend their kid's inheritance.

mbruce

Platinum Member

I'm a sucker for gadgets. Today I bought a ball micrometer with a spindle turned down by LE Wilson. It'll measure necks just like the 2 other ones. Maybe my kids will reload.

bc sportsman

Full Member

One can only hope the kids carry on with at least some degree of interest. One of my two sons does. The other is too busy keeping me supplied with grandkids.

shinbone

Junior Member

bc - very interesting results and thanks for posting!

farleg

Platinum Member

Come on bc your tlkg about me as I need idiot proofing

Thanks for posting info great stuff

& go enjoy your SKI holiday stuff

cheers

jakesch

Senior Member

Well I just ordered lee crimp dies for my 6.5 PRC and 300 WM...I guess I will be jumping into this soon. Will probably read and re-read this post once I get them.

rausch

Senior Member

I’m currently building a 33 nosler and contacted Lee about a FCD. The response I got is it could be done but they aren’t taking any custom orders for the foreseeable future. Is there another way to accomplish what the FCD does? I’m planning on running the 235gr HH and the dummy round I seated already seems like it will need some sort of crimp to stay seated to the proper depth. I have not used a crimp die in the past so this is all new to me as are the Hammer bullets. Any suggestions?

ButterBean

Platinum Member

Let me take a look and I'll get back with you

ButterBean

Platinum Member

I think we can use a 338 RUM FCD, I'll need the die and a couple of pieces of dummy loads so i can modify it

rausch

Senior Member

So just to make sure I’m on the same page I should buy a 338 RUM FCD and send you a couple dummy rounds? I will still have to figure out OAL length I want to load first correct? The rifle is nearly done but I don’t have it in my possession yet.

ButterBean

Platinum Member

I just need the 338 RUM FCD die and 2 pieces of correctly trimmed brass with bullets in them

bojo34

Full Member

Thanks for the tutorial on Crimping BB. Going to give it a shot but a couple questions for experienced crimpers on this sight:

1) does crimping increase pressure all else equal? Just wondering if I should just add a slight crimp to my established load, which is 1gr under first signs of pressure, or if I should back down a bit on powder when adding the crimp?

2) I have not been in the practice of measuring neck tension, just use a standard RCBS FL resizing die. Would it be futile to just add the crimp without also measuring neck tension? Obviously optimal to do both but for those of us under time constraints and wanting to keep things as simple as possible thinking a crimp alone would still probably help, no?

bc sportsman

Full Member

Hi Bojo34, I defer to BB on most things related to shooting. However, while waiting for his response, take a look at data at the top of this page. I posted velocity changes with changes in crimp pressure and keeping neck diameter (4 thou) consistent. Best to read my results on a wider screen because of number of columns.

ButterBean

Platinum Member

Hey Bud, Yes it will increase pressure ( Look at BC's post ) and yes just adding the crimp by its self will help

mcd

Senior Member

Adding the crimp does not necessarily increase pressure. In fact, if the powder you’re using is slightly too slow, the crimp will actually lower pressure. In order to know this for sure, you’d have to have pressure sensing equipment. Resultant velocity alone does not tell the whole story. As far as neck tension, I personally prefer the standard .002” with a strong crimp. It doesn’t mean it’s right, but from what I’ve seen in pressure curves, it results in a positive initial ramp, with a flatter, lower pressure peak that is more consistent. Fine tuning for optimal barrel timing can be tuned through the crimp strength, up or down a little, but I always start strong. Tighter neck tension, in my limited testing, has proven to be peakier, and less consistent shot to shot.

ButterBean

Platinum Member

I've never had a crimp lower pressure and I mean no offense but I just don't buy in to all the pressure curves and strain gages , I always start with the lightest crimp possible and work up, I appreciate all the information but to much information takes the fun out of it for me All the graphs and printed paper information make the Needmoor untouchable but in the end its just a piece paper once again no offense

mcd

Senior Member

No worries. You’ve fine tuned your process over the years, and it works well. I could probably guarantee you your pet loads would look very good on the PTII because of all the care and precision you do in development. As I mentioned, my testing with the system is somewhat limited in sample size as all the work has taken place relatively recently, but it is what I’m seeing for certain scenarios. I need to add that with the strong crimp, I always seat far off the lands on purpose. Those two go hand in hand. How I develop loads now is ensure a clean, consistent pressure curve. From there, it’s usually very easy to settle on a node. 100% of those combinations shoot on top of each other with a very low ES. Sample size is small, relatively, but the trend is unwavering. I find myself shooting far less development loads to get to pet recipes.

carsyn22

Senior Member

That's a bunch of great info!

ButterBean have you ever messed with a 25-300 win mag? No particular reason, I just saw some brass for sale here in SK and thought of you with your affinity for 25's and speed

bc sportsman

Full Member

Hi mcd, i have both a 2.5 thou and 4 thou neck size mandrell from K&M Precision. I was using the 2.5 thou for Barnes but switched to 4 thou with Hammers based on how slippery these are and Steve saying in one of his posts that he sometimes doesnt bother expanding the neck after FL sizing. However, at the time of Steve's post, he wasnt taking into account doing any crimping to tune.

I now always use the Lee FCD, thanks to BB's thread on this. I was successful varying crimp pressure to tune the load based on input from Butterbean, you and other very knowledgable guys and got my groups to noticeably tighten.

Based on your and BB comments above, I'm guessing I should use my 2.5 thou mandrell, rather than my 4 thou, and then fine tune OBT by increasing crimp pressure from light to heavy. I would find it easier to go in one direction re crimp pressure as per BB as opposed to starting somewhere in the middle. My personal preference just in case the optimum crimp pressure is on the light end.

Id appreciate your thoughts and thanks for the insight on neck tension.

mcd

Senior Member

Your approach seems good to me. For me, I always prefer to keep the bullet in place due to recoil, so I tend to want to keep it in place with a tighter crimp for that reason. My favorite rifle, my NULA 300 WM, is very light and kicks very fast. It’s pretty tough on bullets staying put. My methods bend around its propensity to dislodge bullets. It’s worked very well, so I’m adopting that approach to everything. The key is getting consistency from the beginning of the burn cycle and ending on a favorable barrel node for ultimate precision. No doubt several methods can achieve that successfully but utilizing different paths.

farleg

Platinum Member

Gday mcd

Ok guys time for the idiot taswegian to get on board & work this out as I believe this is extremely important & especially for new reloaders As my first concern is safety as I’m sure everyone is

First off this is me

I work up loads from a loading manual ( yes old school still ) start @ start load & work towards max then I push the limits if no pressure was found

Now move to FCD

The lee docents say It’s best to start with a Little crimp & add more just like the reloading manuals ( see attached pic )

So in conclusion I may be reading / interpreting this wrong ( which does happen)

Bojo34 has asked for clarification & to me I’d start a bit low again ( Maybe his 1 gr is sufficient I don’t no ) (Just like in manuals & FCD ) . Is this correct advice ?

Now I’ve got no pressure gauges so i look for pressure signs

So could you please explain with all being equal how can you get a strong crimp to give less pressure vrs a light crimp giving more

I’m not having a go as what concerns me is if someone else interprets like me

Eg I’ve got a slow powder with no or little crimp that’s got pressure so I’ll just go give a strong crimp ( that could be fully crimped for some ) & pressure will be reduced so I’m ok

Me personally I think that’s a very dangerous Scenario & why I’ve given my 5 cents on this

No offence intended just want clarification & safety first

Cheers

bc sportsman

Full Member

Hi mcd, can u please clarify what u mean when u say tighter neck tension results in peakier pressure curve.

Are u saying that about a load that solely relies upon heavy neck tension due to case neck diameter, say 4 thou, without any crimping?

Or...

Are u saying that the steeper curve ALSO happens when u combine heavy neck tension and a crimp?

I wonder if the presence of even a light crimp might act to negate the effect of heavy neck tension.

This is way above my lowly pay grade to figure out so appreciate hearing from all who have insight.

ButterBean

Platinum Member

ButterBean have you ever messed with a 25-300 win mag? No particular reason, I just saw some brass for sale here in SK and thought of you with your affinity for 25's and speed

No I have not, The biggest 25 cal I've done so far is the Hot Tamale ( 25 STW ) but I have seen something new that hasn't been done yet and has sparked my interest and has my ticking as Farleg would say and I'm studying hard on it

mcd

Senior Member

Farleg and bcsportsman,

The 1/2 turn crimp, as suggested by Lee is actually a pretty hefty crimp. It’s where I start though. It can go higher, but not too much. However, I’ve never had to yet

In answering the neck tension question, a tighter neck without the crimp has shown an increase in the burn rate of the powder used significantly. The curve climbs faster all the way to the top. This is with such a small sample size, but the effect was so significant, I completely avoided it any further. In some cases, that may be needed or desired and potentially, the behavior could be different. In the instance I was looking at, it definitely wasn’t as the powder was the right burn rate from the start. For whatever reason, the crimp loads differently. It surges up to between 5-10 ksi then flattens out at release with the bullet continuing forward on a gentler slope up. If done correctly, all bullets share the same time curve up front

The reason I say a slower powder without a crimp may actually have a higher pressure relates to the beginning phenomenon of using a powder with too little charge weight which is an extreme case. The resultant curve looks to like it has a slight hang fire, then it sweeps upward hard. In factory load examples where a light crimp created a delay versus the others, that load started late, had a lower velocity, and a peak pressure maybe 250-1000 psi higher than the other loads.

Remember, our loads are a complex relationship of individual contributions convoluted with interactions. So many things can change different aspects of the burn cycle. What I’ve found has worked so far in every instance, albeit only a few.

mcd

Senior Member

Let me add one thing as I missed a point by farleg. I would always throttle back a hair on powder anytime I make a change. Way better to be safe and burn a few more rounds than be sorry. I don’t even know how I failed to mention that.

A bit more color on the tighter neck tension with crimp. I have not done that specifically yet. That’s what butterbean does, and has laid out in this post, and has proven successful for him for quite a while. Very hard to argue against that.

The reason I stick with the .002” normal interference fit is because I’m able to manipulate anything I need/want with the crimp die. It’s the discovery path I took when incorporating the PTII, and it’s been rock solid so far. It’s way easier to manage due to normal dies being able to be used in their entirety, and bullets aren’t damaged during seating.

mcd

Senior Member

Now that I'm on my computer and not on the phone, here's an example of two factory rounds. Notice the green one that clearly had an inferior crimp to the blue one actually has a slightly higher end pressure. The velocities for both were almost identical at:

Blue - 2998 fps

Green - 3000 fps

You would think these would shoot tight based on the ES, but they did not, of course, based off muzzle exit times.

bojo34

Full Member

Thanks all....great information. I was likely going to back off on powder charge in the sprit of conservatism anyway just curious on people's experience with crimping's affect on pressure. Did scan BC's table but, again, curious if anyone else had seen different results. As noted anytime a component/process to load workup changes it would be prudent to affectively start the process all over, which is what I will do.......certainly should make Steve happy! Currently under a foot of fresh snow here on the east coast so will likely be awhile before I can report back with progress.

Cheers

ButterBean

Platinum Member

If you have a load that's shooting good but needs improvement that's where I would start but that's just me

farleg

Platinum Member

Gday mcd

Think I understand

cheers

mbruce

Platinum Member

I might be off but I look at it like this: Neck tension grips the bullet with friction. Crimp grips the bullet by indenting. They want to achieve the same result.

The less bearing surface touching the neck, the less friction. The less friction the faster powder you may need.

Crimping is a polarizing topic because mostly Lee is the only one producing a rifle crimp die. Also, few —in the grand scheme— shoot bullets with small bearing surfaces. So the crimp die is unfamiliar to the majority. In the Hammer world the majority might be wrong. But it is reasonable for most reloaders to be skeptical

ButterBean

Platinum Member

Your spot on, I was using the Lee FCD long before Hammers were around with great success , and yes the Hammer really responds to it but there will always be the nay sayers, on the LRH forum one of the greatest guys there and renowned gunsmith JE Custom finally got curious enough and did a test for himself, the results surprised him, do you need to crimp ???? Nope, folks been shooting along time without crimping, I've been shooting a long time and I crimp everything and I have never seen any disadvantages if done correctly

littlebighorn

Full Member

Well ButterBean, I just gave two Lee FCDs to my wife to give to me for Christmas.

I hope she's not disappointed!

ButterBean

Platinum Member

I'm sure she'll love em

farleg

Platinum Member

Well my first FCD showed up today in 6.5 grendel. So naturally I ordered some 99gr HH to try today as well. I’m really excited about the potential of this combo in my suppressed AR. I’ve got a crimp die on the way for my .300 WM but haven’t settled on which bullet to try in that setup yet. I currently shoot 180 AB’s but I was thinking of dropping weight a little there because my custom .33 nosler is done and I’ll be shooting a heavier bullet out of that setup.

Gday rausch

I like & why your thinking lighter I couldn’t help but put my bit in

why not go to the 137 out of the 300 wm & get them cranking

within a 400/500 range no animal would walk away from those

cheers

carsyn22

Senior Member

I also asked for a FCD in 300wm for Christmas! Thing is though, if I don't get it then I will just go buy one HAHA!

rausch I agree with going light and fast in the 300wm, as you mentioned you have a .33 for heavy, I went with the 178 AH only because it was the first AH available when I ordered and I didn't want to wait any longer, but the 151 AH would get more speed. Or like Farleg said the 137 might be worth a good look too!

All the best and Merry Christmas!

farleg

Platinum Member

Gday carsyn22

i heard a rumour that Santa only comes to good kids lol so we all should get what we’ve asked for