Koda

Hammer Time Executive member

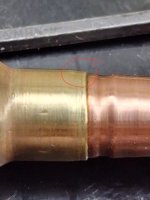

All my other Lee FCD's produce a nice taper crimp that lays nicely on the PDR slope. My Lee FCD for my Grendel produces some kind of squeeze ring crimp. Its as if the pressure is squeezing directly in instead of at an angle. I didn't know Lee made 2 kinds of FCD's and cant find one that tapers in their Grendel. The Lee Grendel crimp for my Grendel requires a heavy 1/4 turn to help hold the bullet, mars up the neck rim badly that stays and gets worse with each reloading.

Can anyone recommend a different brand crimp die for a 6.5 Grendel that produces a taper crimp?

Photo: Grendel crimp on the left, 280ai crimp on the right. Both are Lee FCD's.

Can anyone recommend a different brand crimp die for a 6.5 Grendel that produces a taper crimp?

Photo: Grendel crimp on the left, 280ai crimp on the right. Both are Lee FCD's.