You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Brass Analysis by Pressure Signs

- Thread starter BFD

- Start date

joe16

Hammer Time Executive member

If I hadn't given away all of my 7-08 stuff, I would have gladly donated it to this cause@joe16, if you’ll get us some Peterson or something we can do those measurements

The most important thing we do is come home to our family with all our fingers and toes.

That being said I'm also a proponent of running to the edge, the safe Edge. It might not be the most economical, but that's my choice. These are hunting rifles that I might shoot 10 times a year, at my age 50 pieces of premium brass (run like a dog) will last my lifetime.

LightTheTower

Hammer Time Executive member

I ordered .175, .178, .210, and .213 pin gauges from Amazon for about $3 a piece.

BFD

Hammer Time Executive member

Gettin fancy!I ordered .175, .178, .210, and .213 pin gauges from Amazon for about $3 a piece.

BFD

Hammer Time Executive member

My 708 brass is a one & done, fire & forget, cause it ends up in the canyons & mesquites. It gets beat up through the cycling of the AR10 platform. All I want out of that brass is they hold the primers in the brass so they don’t pop out into the fire control group and render the gun inoperable. I buy bulk brass at $.20 a piece for this.If I hadn't given away all of my 7-08 stuff, I would have gladly donated it to this cause

The most important thing we do is come home to our family with all our fingers and toes.

That being said I'm also a proponent of running to the edge, the safe Edge. It might not be the most economical, but that's my choice. These are hunting rifles that I might shoot 10 times a year, at my age 50 pieces of premium brass (run like a dog) will last my lifetime.

My bolt guns with Lapua & Peterson is where I like things smooth going to get 4-5 hunting load pressure shots. My range brass I want 15 min loads because I let the high BCs of Bergers, Hornady, & Sierras.

I also shoot my stuff considering the powder temp and shoot in the colder load development temps with the ammo heated 100F. That way I don’t get any primer pops in 100F weather.

My info here is a technique that I think the best way to measure pressure, wherever a guy wants to be, by eliminating the “Reading the tea leaves” and stick to some measurements that can be easily verified with relative & absolute measurements.

In regards to brass. Federal 308 WIN seem to give up the ghost quicker on pockets than others I’ve tried. Schmo’s Nosler is way impressive in the regard. I’m giving Remington bulk a go again remembering the beatings I put on them in the 2000s firing M1As, FALs, AR10s. FAFO always!

BFD

Hammer Time Executive member

Should further illustrate@BFD, I think would be a good place to also include a picture demonstration of web measurement and where the "200 line" is located. This should help new reloaders to know where and what we are talking about.

When are Pressures Too High? « Shooters Notes

ButterBean

Hammer Time Executive member

Y'all know I push everything to the edge so i will add to this and tell you I have found ( By accident) that most of my brass after 3 firings the web has expanded enough that the die won't go over it and oh yeah, I Love This Place

joe16

Hammer Time Executive member

The first 300 rum I had was a Savage 116 with the adjustable muzzle brake. The chamber was slightly larger than normal And after two firings Of Nosler and Remington brass, this was about 12 years ago.( wow that was a ramble ) I had to make a small base die to continue using the brass. I had two sets of dies and preferred the Lees over the hornadys so I sacrificed the Hornady full length sizing die by hacksawing off a quarter of an inch off the bottom and cut the top off right at the shoulder. A whole bunch of grinding produce something that looked like Frankenstein had created. I took it to the Machine Shop to have it squared up and chamfered, after that I never looked back.

) I had to make a small base die to continue using the brass. I had two sets of dies and preferred the Lees over the hornadys so I sacrificed the Hornady full length sizing die by hacksawing off a quarter of an inch off the bottom and cut the top off right at the shoulder. A whole bunch of grinding produce something that looked like Frankenstein had created. I took it to the Machine Shop to have it squared up and chamfered, after that I never looked back.

I had Pac Nor build me a 300 Rum Barrel and I've never had to use the die on that particular rum. Chamber variations have a lot to do with what you're seeing in your brass is partly my opinion.

Joe

I had Pac Nor build me a 300 Rum Barrel and I've never had to use the die on that particular rum. Chamber variations have a lot to do with what you're seeing in your brass is partly my opinion.

Joe

If you use a 1” micrometer and measure right above extractor ring when it expands .0003-.0005 you are at pressure and this shows before primer, extractor mark or hard bolt lift and right before it gets there is usually where it shoots best .0001-.0003. Give you a safe accurate load at any condition. Good luck

ButterBean

Hammer Time Executive member

I like your styleThe first 300 rum I had was a Savage 116 with the adjustable muzzle brake. The chamber was slightly larger than normal And after two firings Of Nosler and Remington brass, this was about 12 years ago.( wow that was a ramble) I had to make a small base die to continue using the brass. I had two sets of dies and preferred the Lees over the hornadys so I sacrificed the Hornady full length sizing die by hacksawing off a quarter of an inch off the bottom and cut the top off right at the shoulder. A whole bunch of grinding produce something that looked like Frankenstein had created. I took it to the Machine Shop to have it squared up and chamfered, after that I never looked back.

I had Pac Nor build me a 300 Rum Barrel and I've never had to use the die on that particular rum. Chamber variations have a lot to do with what you're seeing in your brass is partly my opinion.

Joe

BFD

Hammer Time Executive member

I'm finding the primers, made of different sizes and properties, and placed in primer pockets of brass with different designs in support of the primer in the pocket, are not a consistent indicator of pressure levels. I am also finding primer pockets diameter grow faster than the web diameter when pushed for pressure testing.If you use a 1” micrometer and measure right above extractor ring when it expands .0003-.0005 you are at pressure and this shows before primer, extractor mark or hard bolt lift and right before it gets there is usually where it shoots best .0001-.0003. Give you a safe accurate load at any condition. Good luck

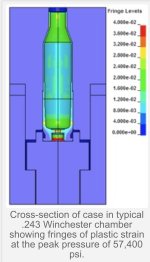

This illustrative picture appears to support my findings in that the most pressure stress measured, the red color in the pocket, and also indicating most elasticity/plastic deformation occurs in the primer pocket.

Last edited:

BFD

Hammer Time Executive member

@joe16

@aratliff

KISS explanation here. So, in the thread "Reading Pressure Signs" by @Schnittker, and then addendums by fellow Hammerheads, popping the primer and examining the shape of it was a method explained. An hourglass shape indicated stout/over pressure. I found that can't be universally applied considering the popped primers from my Peterson brass were hourglass shaped, but occurred on quite lighter charge weights when initially beginning the load development process with the new Peterson brass. Closer inspection revealed Peterson brass doesn't fully support the primer to the very top, in contrast to Lapua where there is a collar inside the pocket that does extend to the top of the primer. In essence, I was getting a false read of pressure because every primer coming out of the fired Peterson brass was hourglass shape.

What seems to be universally applicable to find pressure is the primer pocket and web growth in comparison/relative measurement to baseline/virgin brass measurements.

With that said, I'm lucky enough to have a Savage 110 Elite action that will show me stout pressure when the 215M primer craters. If I can catch a fingernail on the divot, I'm in the high end of my allowable pressure. Contrasted to no crater and smooth across the divot when I'm in the brass savings pressure bracket. This discovery came by simply knowing the nuances through familiarity and observation of my rig. Now, some rifles have firing pins that will crater everything, and thus not a reliable indicator to pressure and I then suggest looking at the primer pocket growth and web as already explained previously and in ad nauseum.

@aratliff

KISS explanation here. So, in the thread "Reading Pressure Signs" by @Schnittker, and then addendums by fellow Hammerheads, popping the primer and examining the shape of it was a method explained. An hourglass shape indicated stout/over pressure. I found that can't be universally applied considering the popped primers from my Peterson brass were hourglass shaped, but occurred on quite lighter charge weights when initially beginning the load development process with the new Peterson brass. Closer inspection revealed Peterson brass doesn't fully support the primer to the very top, in contrast to Lapua where there is a collar inside the pocket that does extend to the top of the primer. In essence, I was getting a false read of pressure because every primer coming out of the fired Peterson brass was hourglass shape.

What seems to be universally applicable to find pressure is the primer pocket and web growth in comparison/relative measurement to baseline/virgin brass measurements.

With that said, I'm lucky enough to have a Savage 110 Elite action that will show me stout pressure when the 215M primer craters. If I can catch a fingernail on the divot, I'm in the high end of my allowable pressure. Contrasted to no crater and smooth across the divot when I'm in the brass savings pressure bracket. This discovery came by simply knowing the nuances through familiarity and observation of my rig. Now, some rifles have firing pins that will crater everything, and thus not a reliable indicator to pressure and I then suggest looking at the primer pocket growth and web as already explained previously and in ad nauseum.

Share: