You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extreme copper fouling

- Thread starter DiscoSteve

- Start date

Koda

Hammer Time Executive member

With only hammers.... my guess is the lands have a lot of chatter maybe... and will smooth out after settling in.Thanks @Koda. Gunsmith said he didn't test fire it, so all of that fouling is from my 7 shots. Hard to believe. I'll get it cleaned back to bare metal best I can and then try again. Thanks again.

As long as it shoots good, alls good. IMO everyone should get a borescope especially on a new barrel, no other way to assure clean.

To clean, run a couple patches with Kroil oil down the bore and let soak in a few minutes. Then put some JB paste on a patch and use an old worn out brass brush (with bronze core). Wrap the patch with JB bore paste around the old brush and give the barrel 10-12 strokes. Discard the patch (it should be filthy). Repeat until patches stop coming out black (light gray is ok).

Then use patches with Kroil to remove all JB abrasive (4-5 more patches.).

JB is a very mild abraisive but cleans copper, carbon and other junk very well.

When you get clean Kroil patches out of the bore, take another look with your borescope. Just a few cycles of JB should correct your woes.

My bet is you have a button rifled barrel with some tool chatter present. Hopefully it will smooth out over time and firing .

.

Then use patches with Kroil to remove all JB abrasive (4-5 more patches.).

JB is a very mild abraisive but cleans copper, carbon and other junk very well.

When you get clean Kroil patches out of the bore, take another look with your borescope. Just a few cycles of JB should correct your woes.

My bet is you have a button rifled barrel with some tool chatter present. Hopefully it will smooth out over time and firing

DiscoSteve

Hammer Time Executive member

Awesome, thanks fellas. I might have to pick up some kroil and jb paste.

Since the fouling starts mid barrel, I was reading that this is from small pieces of copper getting vaporized and then traveling down the barrel mixed in with the hot combustion gases and getting deposited farther down toward the muzzle. Some claim this is from a rough throat causing the copper pieces in the first place. Anyone think that’s valid? It’s weird to me that the first half of the barrel is pristine, and then a copper mine starts mid-barrel.

Since the fouling starts mid barrel, I was reading that this is from small pieces of copper getting vaporized and then traveling down the barrel mixed in with the hot combustion gases and getting deposited farther down toward the muzzle. Some claim this is from a rough throat causing the copper pieces in the first place. Anyone think that’s valid? It’s weird to me that the first half of the barrel is pristine, and then a copper mine starts mid-barrel.

DiscoSteve

Hammer Time Executive member

Gotcha. Where should I look for that with the borescope? The throat? Right where the rifling starts? I noticed there’s a “rough spot” or a “divot” just past where the case mouth would end. Anyway, thanks again for all the advice. Hopefully this will help someone else out as well!That's what I meant by tool chatter.

BFD

Hammer Time Executive member

Thorroclean kit followed by dry graphite in the barrel. Repeat every 20rnds and the copper fouling will subside.

You can get the PVA "Plug" and fill the bore with Hoppes Black Copper Solvent an let sit overnight. Won't harm barrels like that absolute Satan's spit Wipeout products.

A barrel that coppers like that wasn't hand lapped very good at all.

You can get the PVA "Plug" and fill the bore with Hoppes Black Copper Solvent an let sit overnight. Won't harm barrels like that absolute Satan's spit Wipeout products.

A barrel that coppers like that wasn't hand lapped very good at all.

Last edited:

Tool chatter is very tough to see without Very expensive borescopes and good focus.

When you clean your barrel you Can often "feel" rough spots.. when you clean, you may feel resistance at a point then after cleaning/shooting (breaking in) the barrel becomes smoother. At that point, copper fouling should subside.

BFDs suggestion of adding graphite is an up and coming process and gaining traction. Personally, I haven't tried it, but it makes sense.

Many now add graphite to a clean bore to simulate firing & fouling the bore before a cold barrel first shot.

When you clean your barrel you Can often "feel" rough spots.. when you clean, you may feel resistance at a point then after cleaning/shooting (breaking in) the barrel becomes smoother. At that point, copper fouling should subside.

BFDs suggestion of adding graphite is an up and coming process and gaining traction. Personally, I haven't tried it, but it makes sense.

Many now add graphite to a clean bore to simulate firing & fouling the bore before a cold barrel first shot.

Koda

Hammer Time Executive member

I think were overthinking this here. You have a new barrel, it has some copper fouling. I would just worry about getting the fouling out, keeping it out (clean) and enjoy shooting the gun. Its a new barrel, it will settle in as you fire it and be what it is. Any imperfections in the making of the barrel are what they are and cant be undone.Gotcha. Where should I look for that with the borescope? The throat? Right where the rifling starts? I noticed there’s a “rough spot” or a “divot” just past where the case mouth would end. Anyway, thanks again for all the advice. Hopefully this will help someone else out as well!

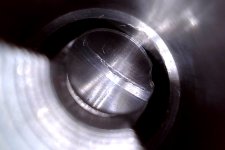

But to answer your question, chatter can be anywhere the tool vibrated or skipped during its process. Heres a pic of my barrel, the lines that are perpendicular to the path of the bore are chatter. If a tool is fed along its path too fast it can vibrate or skip leaving a mark. Im a little over my head here as Im not familiar with how rifle bores are made so anyone is welcome to correct my assessment here.

You are basically correct. Some chatter is normal with button rifling. If a tool begins to wear, is damaged, or speed changes occur during the rifling cutting, deeper than normal chatter can occur.

This is exactly why many manufacturers specify a "break in" procedure. Shoot 1, clean, repeat 5 times, then shoot 5 and clean, 5 times, etc.

The purpose is to gradually remove fouling as the bore smooths out (and usually gains a little speed) during the process. Speed gains of 50 fps or more are common in the first 100 rounds or so.

This is exactly why many manufacturers specify a "break in" procedure. Shoot 1, clean, repeat 5 times, then shoot 5 and clean, 5 times, etc.

The purpose is to gradually remove fouling as the bore smooths out (and usually gains a little speed) during the process. Speed gains of 50 fps or more are common in the first 100 rounds or so.

joevh

Hammer Time Executive member

I bought a bore scope last winter, and I will say that it has revolutionized my idea of cleaning a barrel. That being said, I can relate to the guys that just don't want to know, as it can become obsessive. To your point, in my experience, all of my barrels start copper fouling around the middle, the worst of it being about 3/4 down the barrel. I don't know why, but that's where all of mine show it, so I wouldn't read too much in to the location of the copper.Awesome, thanks fellas. I might have to pick up some kroil and jb paste.

Since the fouling starts mid barrel, I was reading that this is from small pieces of copper getting vaporized and then traveling down the barrel mixed in with the hot combustion gases and getting deposited farther down toward the muzzle. Some claim this is from a rough throat causing the copper pieces in the first place. Anyone think that’s valid? It’s weird to me that the first half of the barrel is pristine, and then a copper mine starts mid-barrel.

It seems that I'm constantly in search of the best method of cleaning and which products to use, but I've had great success with cleaning the carbon out with a good bore cleaner, then a couple patches with Barnes CR-10 copper remover (Barnes is probably the king of copper fouling, so they should know something about removing it), then about 25 strokes with a plastic brush, then another patch, repeat as necessary.

Despite the higher cost of Hammer bullets, I've become very reluctant to shoot anything else even for fun or breaking in a barrel, just because I hate cleaning out copper. When working up a load and sighting in my 300 WSM with 154 HHT's, I went through about 15 rounds and then bore scoped it - not even a hint of copper.

DiscoSteve

Hammer Time Executive member

Thanks everyone for their advice and input - I appreciate it. My plan is to clean it best I can with what I have (got some new cleaning products on the way!) and start by shooting a few single shots with cleaning in between. Then 3 shots strings, clean, then 5 shot strings. Maybe for the first 50 rounds or so? At some point "barrel break in" and "shooting" become the same thing.

@joevh - I have some barnes copper cleaner, maybe I'll focus on that.

@Koda - thanks for the borescope pics. I'll have to take a closer look at mine to see if there are any tool marks.

@BFD - how do you apply the graphite to the barrel? Just sprinkle some on a patch and run it through?

@joevh - I have some barnes copper cleaner, maybe I'll focus on that.

@Koda - thanks for the borescope pics. I'll have to take a closer look at mine to see if there are any tool marks.

@BFD - how do you apply the graphite to the barrel? Just sprinkle some on a patch and run it through?

BFD

Hammer Time Executive member

I put a patch in an open top small plastic dish with BBs. I pinch it with a small pair of needle nose pliers and dirty the thing up in the graphited BBs till it's solid black. Then I work it into the rifling with a few 1/4 barrel length strokes then a couple full length strokes.Thanks everyone for their advice and input - I appreciate it. My plan is to clean it best I can with what I have (got some new cleaning products on the way!) and start by shooting a few single shots with cleaning in between. Then 3 shots strings, clean, then 5 shot strings. Maybe for the first 50 rounds or so? At some point "barrel break in" and "shooting" become the same thing.

@joevh - I have some barnes copper cleaner, maybe I'll focus on that.

@Koda - thanks for the borescope pics. I'll have to take a closer look at mine to see if there are any tool marks.

@BFD - how do you apply the graphite to the barrel? Just sprinkle some on a patch and run it through?

Barnes CR-10 is pretty darn good BUT please read and follow their directions of use. It is VERY aggressive so do not extend any of their times of the ammonia based cleaner in the barrel.

7.62 Sweets copper cleaner is also another aggressive copper cleaner and again follow their directions to the letter.

They REEK! Either one, I have to burn a candle away from bench to burn off the volatiles. Obviously, don't burn candle on bench. Or preferably clean them at range on bench in open air. My wife gave me old candles after one copper cleaning session when I heard "what the H*** are you doing in basement? It reeks up here!! Oh yeah, make sure you blow out candle when done. Yes to the question.

They work especially well when combined with JB. BTW, get some quality nylon brushes for copper removing.

They REEK! Did I mention this?

7.62 Sweets copper cleaner is also another aggressive copper cleaner and again follow their directions to the letter.

They REEK! Either one, I have to burn a candle away from bench to burn off the volatiles. Obviously, don't burn candle on bench. Or preferably clean them at range on bench in open air. My wife gave me old candles after one copper cleaning session when I heard "what the H*** are you doing in basement? It reeks up here!! Oh yeah, make sure you blow out candle when done. Yes to the question.

They work especially well when combined with JB. BTW, get some quality nylon brushes for copper removing.

They REEK! Did I mention this?

joevh

Hammer Time Executive member

BFD, I'm glad this question was asked, as I've been wondering about it. Do you store rifles long term (after hunting season...) with just the graphite in a clean bore, or do you clean and oil them, and then just dry patch and graphite them before you take them out to shoot next?I put a patch in an open top small plastic dish with BBs. I pinch it with a small pair of needle nose pliers and dirty the thing up in the graphited BBs till it's solid black. Then I work it into the rifling with a few 1/4 barrel length strokes then a couple full length strokes.

Good question! X2 interested!BFD, I'm glad this question was asked, as I've been wondering about it. Do you store rifles long term (after hunting season...) with just the graphite in a clean bore, or do you clean and oil them, and then just dry patch and graphite them before you take them out to shoot next?

BFD

Hammer Time Executive member

The graphite only gets applied to the guns during the shooting season. Definitely not for storage! In the off season the guns get cleaned and a heavy dose of gun oil stays in the bores with a tag that says, "OIL YOU DUMMY, CLEAN BEFORE SHOOITING!"BFD, I'm glad this question was asked, as I've been wondering about it. Do you store rifles long term (after hunting season...) with just the graphite in a clean bore, or do you clean and oil them, and then just dry patch and graphite them before you take them out to shoot next?

DiscoSteve

Hammer Time Executive member

Update: I shot about 15 more rounds through it this weekend. Cleaned in between each of the first 5 shots. Then shot 3 shot strings and cleaned (used some old accubonds and swift A-frames I had lying around). I got some thorroclean and thorroflush, and they seem to work very well, and don't smell at all. Also proshot copper solvent IV seems to work well on the copper if you let it sit for a while. Still waiting on the kroil and JB paste.

I found it takes about 3 "cycles" of the thorroclean to get close to bare metal. I define a "cycle" as a few wet patches of thorroflush, followed by a nylon brush coated in thorroclean for 20 strokes down the barrel, followed by more patches soaked with thorroflush until they come out clean. It takes a while.

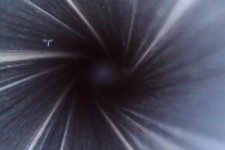

The attached pictures are about as clean as I can get it, and the next one is after ONE shot! I looked down all my other barrels, and there's nothing even close to this amount of copper fouling. Could it be from this rough spot on the throat?

I found it takes about 3 "cycles" of the thorroclean to get close to bare metal. I define a "cycle" as a few wet patches of thorroflush, followed by a nylon brush coated in thorroclean for 20 strokes down the barrel, followed by more patches soaked with thorroflush until they come out clean. It takes a while.

The attached pictures are about as clean as I can get it, and the next one is after ONE shot! I looked down all my other barrels, and there's nothing even close to this amount of copper fouling. Could it be from this rough spot on the throat?

Attachments

Share: