“Learning Pressure Signs” an addendum.

More discussion on:

ejector marks,

gas leakage,

primer cratering,

case head expansion,

primer pocket expansion,

cold welding

@ Schnittker and others’ discussions on pressure and it’s affect on primers is excellent. One would do well to study his photos and discussions in depth. To assist in understanding all of the above, several members have contributed their knowledge of the topic to try to make this post a one-stop-shop of information for those who are new to hand loading center fire rifle cartridges.

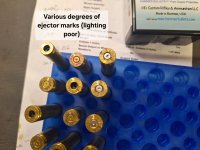

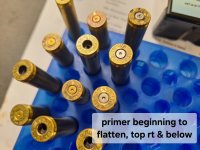

Let’s start with more photos of fired cartridges, showing light to strong ejector marks and gas seepage which can occur when nearing too much pressure or when primer pockets are getting worn out and beginning to leak. Gas leakage can be damaging to a rifle and can result in gas cutting/etching of a bolt face (undesirable).

The first photo is of various degrees of ejector marks, from light to rather severe.

In the second photo, primer cratering is noted in the top right case and the one below it.

Clearer view of gas leakage, flattening primer and primer cratering.

(See Attachments below)

Case head expansion is yet another indication of pressure. This measurement is taken at the “200 line” from SAAMI specs on a cartridge case. It is a measurement of how much the web of the cartridge case stretches due to internal pressure. The web (base) of the case is the strongest portion of a cartridge case. Stretching here directly impacts the primer pocket. It is also a measurement which tells you when the primer pocket is done for and will no longer reliably hold a primer. There is also a tool which will tell you this.

When you fire form a cartridge to your chamber, you remove excess clearance which comes with all new factory brass. New brass is somewhat undersized so it will fit in any chamber cut to that specific cartridge. On the first or second firing, new cases typically expand around .002 (2 thousandths). After that initial expansion, future expansion is shortening the life of the cartridge case/primer pocket. If one shoots mild loads, it’s not uncommon to get multiple loadings on a piece of brass. If you shoot loads on the upper end of speed/pressure, it is not uncommon to only get 2-3 loadings from a piece of brass before the primer pocket is stretched to the point it will no longer hold a primer reliably. Fingernail polish or moisture barrier sealant (same thing) can be used a time or two before gas leakage typically begins – and gas leakage should be avoided. It’s best to trash the brass when primer pockets are ruined/stretched.

First photo is of dial caliper measuring new brass at the 200 line. Initial measurement on this cartridge was .528. After first firing, the web stretched to .530. After 3-4 firings the primer pocket was trashed and the web measured .532.

A safe rule of thumb is keep web expansion to less than1.5 thousandths (.0015) if you want to make your brass last.

(See attachments below)

There are also tools to measure your primer pocket. These are primer pocket go/no go gauges. The one pictured is from Brownells. If the gauge will not enter the primer pocket, the case will hold a primer snugly. If the gauge goes in the primer pocket, it’s time to trash the brass. The beauty of this tool is it eliminates you trying to seat a primer that's not going to stay, or tells you when finger nail polish is in order - (or not).

(See attachments below)

Cold welding primarily affects new brass or brass that has been cleaned excessively. The most common example comes from an individual who loads up a bunch of new brass and then leaves it on the shelf for a couple of years.

If the brass has been fired and the carbon in the neck is not completely removed, cold welding is typically not a problem. The carbon in the neck isolates the bullet from direct contact with the case walls and cold welding is prevented. If the carbon is completely removed by brushing vigorously with a bronze brush or case cleaning with stainless steel pins, cold welding can occur if the ammo sits for an extended period of time.

The photos show a ring of oxidation (?) in case necks and on the base of the bullets after they sat for 2 years waiting for the next prairie dog hunt. This was new brass, waiting to be fire formed while shooting Pdogs. (sorry for the poor quality of the photos. This was from a few years ago)

(See attachments below)

The following are excerpts from other threads. If you have additional pieces that are pertinent to this thread, please add them here or send them to me. This should be very useful to new hand loaders.

Old PDR vs new PDR

Moderator

@BFD,

This is what has seemed to worked for me. Once brass is ready for FL sizing, I brush neck with bronze brush couple swipes to "clean of of debris" not remove carbon, swab neck (CAREFULLY without slobbering it up) with lubricant (I use STP) which I feel helps neck sizing consistency no matter what I use. I then use the "magic" acetone by dipping neck area into small bottle to dissolve the lube out of neck. It dries INSTANTLY ends up squeaky dry. Fast forward to bullet seating, I swirl bullet in graphite, seat bullet, crimp. The graphite statically attaches to bullet so it is there during seating. All I can say is ES SD is very low and loads are accurate. No cold weld. YMMV

Cold Weld Insurance:

New brass could use a thin amount of dry graphite applied to the necks or bullet bases to prevent cold welding.

Fired brass will already have enough carbon residue to provide this thin film between metals. Hence the acetone is only to remove the case lube/neck lube as Muddy stated in his process. (*Considering you don't clean the brass with stainless steel pins or some electrolysis gadget that removes all carbon. Then you would need to add graphite to the fired brass necks)

Precision and Proper Application:

The wet type lubes caused my groups to open considerably. It mimicked groups I would get when firing the initial fouling shots on a clean barrel.

The dry graphite opened the groups a little, but I added too much graphite and skewed the results. Benchrest competition champions use dry lube in the necks, and do so properly, so I trust their results and reporting. (Think of rather a dusting of the dry lube, and not clumping)

Graphite in the Barrel:

Applying dry graphite in the barrel, after a thorough cleaning, will minimize considerably, if not totally eliminate the POI shift of first round shots on a cleaned barrel. This is done by embedding graphite on a patch and then running a combo of short & long strokes through the barrel. Every barrel I've done this graphite treatment on has me printing the first rounds with no discernable difference with POI.

I once set myself up for a blind test of the graphite treatment. I purposefully left a barrel raw after cleaning to gather more data on this procedure. Well, I forgot I did that and ended up shooting it without the graphite treatment. This was an excellent way to eliminate experimenter bias! I was WTF on the first 4 rounds fired and got worried I did something wrong with the load development...then I remembered what I forgot and started laughing at myself. "OK, this graphite thing has become like a law of physics for me!"

Carsyn.22

Brad when you talk about lube in the ID of the neck does that include the LEE sizing lube that dries? That’s what I’ve been using and just leaving it in there… then again I ain’t no bughole shooter like you!

I have methyl hydrate and graphite so I could try a test between the Lee lube and graphite sometime

Yes. Lee, Imperial sizing wax, Hornady one shot, anything slippery wet. No good.

On the graphite. I started using the Aerosol version of lock ease. It would dry after a while, so I would allow a day to 3 to shoot. The lock ease in the liquid form wasn't drying even after a week or more sitting in the barrel. I blew primers on the first two rounds because the liquid was still in the barrel. So, I just use dry graphite in a dish with .177 BBs. Use a pair of needle nose pliers and push the patch around in the graphite till covered black.

Koda

Not a consensus.

Cold welding and case cleaning are two separate subjects.

As far as i know there isn't a consensus on either subject just a discussion on how and why individuals are including these steps in their process.